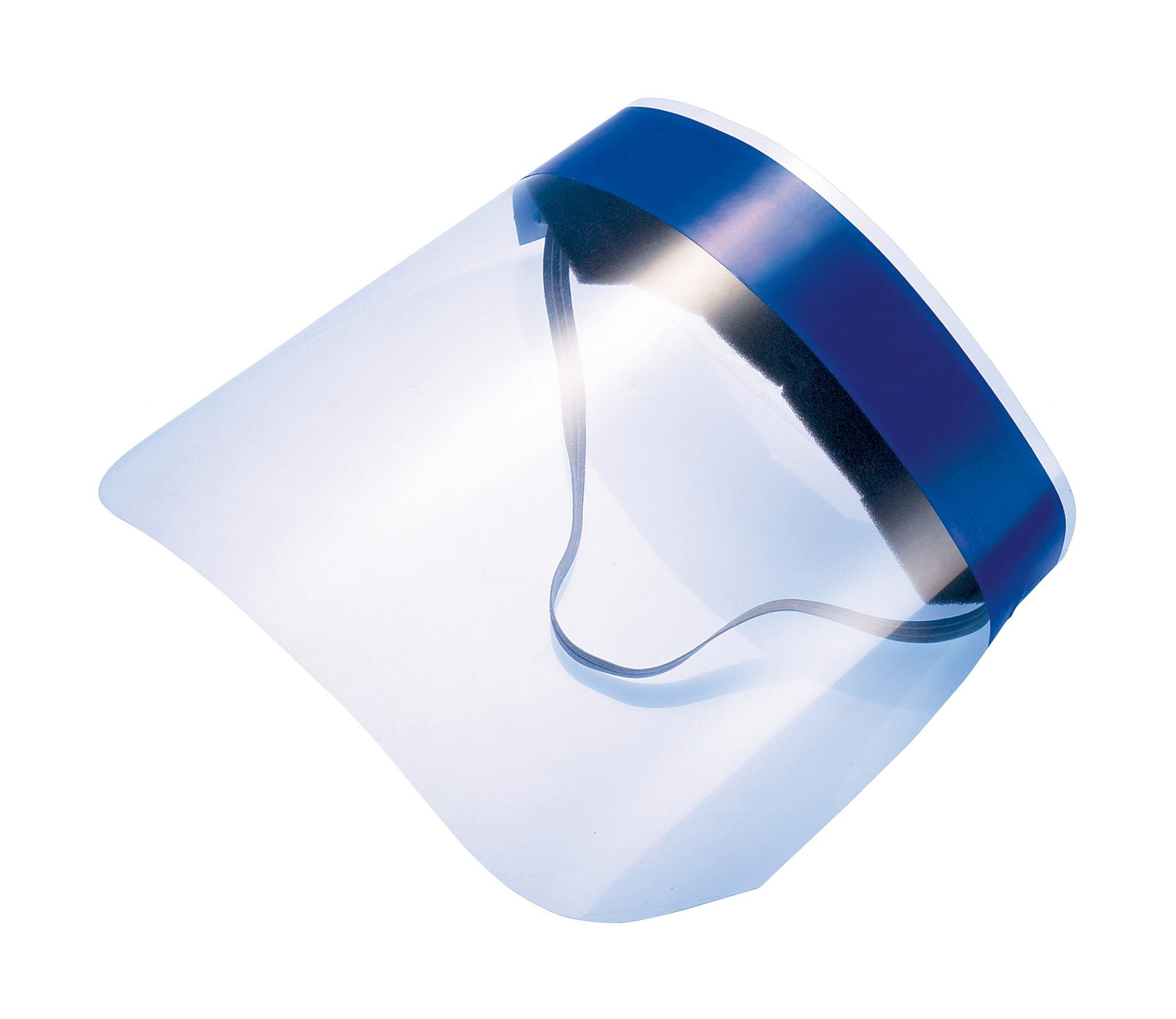

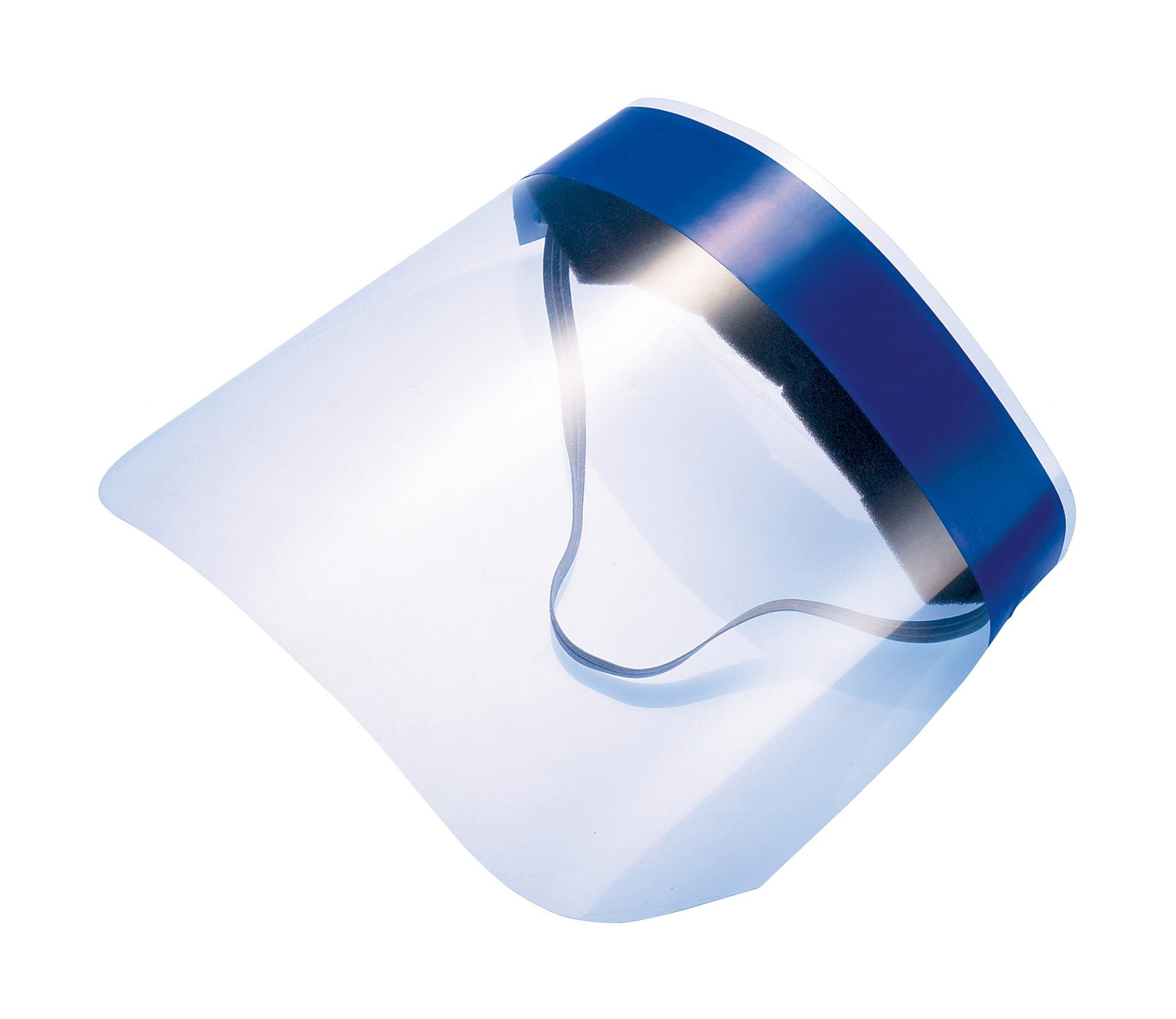

ICP has begun to manufacture face shield components to meet the surging demand from the spread of COVID-19. Using PETG or polycarbonate plastic, we’re diecutting clear shields to be used in the PPE on the frontlines of this pandemic. Our Minneapolis facility also has the capability to die cut foam for face shield components and provide assembly services for a more complete product.

Our nurses, doctors, and hospital workers are face-to-face with COVID-19 every day, and they need PPE more than ever. As plastic manufacturing experts, we’re doing our part to back them up with the equipment they need.

PETG and polycarbonate are both thermoplastics often used in the medical field. Naturally clear and strong, each has the qualities you look for in protective eyewear. In fact, both are many times stronger than glass. PETG can be more easily worked than polycarbonate, making it more economical for many uses. PETG especially can also be resistant to the intense sterilization practices found in the medical field.

Face shields are recommended to be used in conjunction with N95 masks or surgical masks to provide protection against the aerosolization of bodily fluids from infected individuals, which is precisely how COVID-19 is believed to spread. This equipment will save lives.

Supply chains across the world are kicking into high gear to produce PPE, ventilators, and other products to fight this pandemic. ICP is rising to the challenge with its expertise in plastics manufacturing. As an essential business in the pandemic response, ICP will continue its work, contributing to the efforts we all need to undertake together to face COVID-19.

Contact icp@industrialcustom.com for questions and more information about our manufacturing capabilities. You will receive a prompt response.