Manufacturing plastic parts can be executed several ways – but the two most common are injection molding and thermoforming.

Both injection molding and thermoforming use thermoplastics and can produce similar end results – however, they differ in tooling costs and lead time.

What is Injection Molding?

Injection molding is the process of heating thermoplastics into a liquid and then injecting into a mold. This requires a custom mold and tooling for production, and can be costly for short run or lower volume parts. It also has a longer lead time because of the cost of creating a custom injection mold.

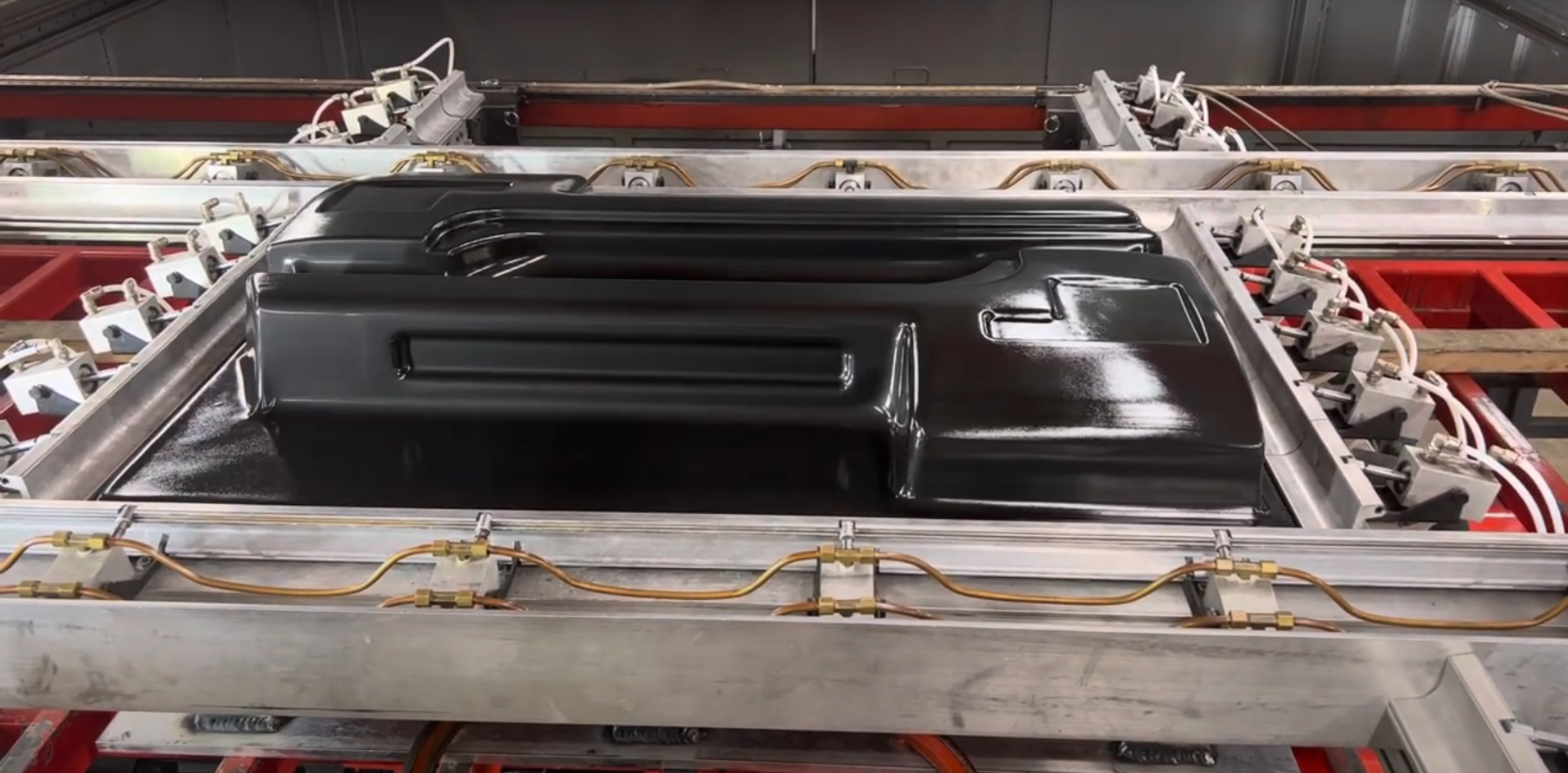

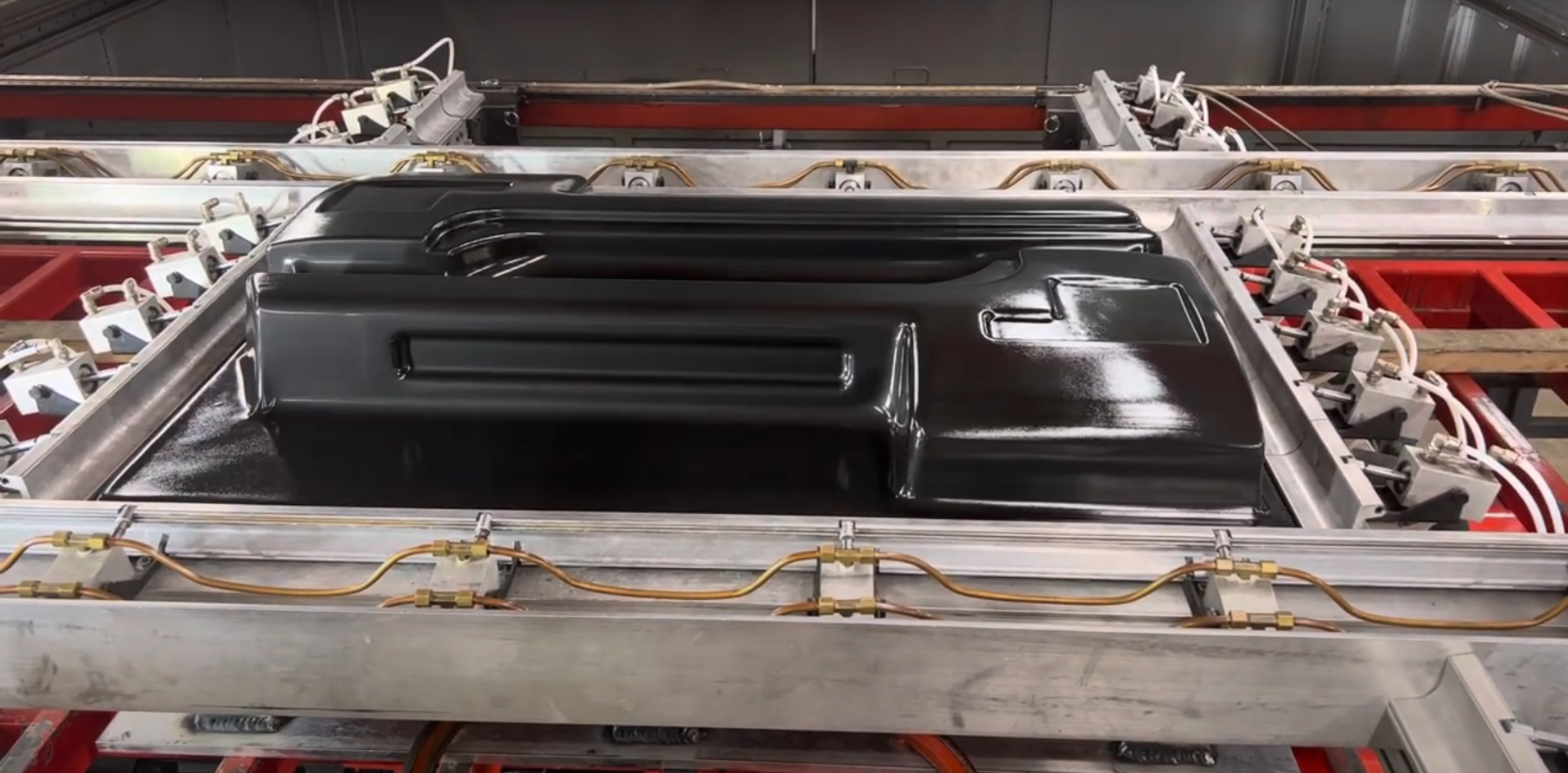

Thermoforming is the process of heating sheets of thermoplastics to be pliable, and then molded into shape using suction from a vacuum. The part can then be modified further with cnc trimming or even hand trimming for the right applications.

Related Content: What to Know About Thermoforming Molds

Quick Comparison

Thermoforming

- Flat sheets of thermoplastics are heated to a pliable temperature, then molded to a tool shape using suction from a vacuum.

- Final pieces can be hand trimmed or trimmed with a multi-axis CNC.

- Lower tooling costs & shorter lead times.

- Very cost-effective for lower-volume and larger parts.

Injection Molding

- Thermoplastic pellets are heated to a liquid and then injected into a mold.

- Final pieces are removed from the mold.

- Higher tooling costs & longer lead times.

- Very cost effective for high-volume parts with a longer life cycle.

Is Injection Molding or Thermoforming Better?

The answer depends on the part design and volume of the project. Injection molding is better for high-volume parts that are smaller and thermoforming is better for lower-volume and larger parts. Thermoforming tooling is much lower in cost so it is a great manufacturing method for many applications.

Consult the ICP team for a design review and budgetary quote to see where thermoforming falls in line with your next project.

Related Content: Thermoforming in a Nutshell

Thermoforming with ICP

Since 1955, ICP has grown to become an award-winning leader in prototyping, developing, and manufacturing high-quality plastic and flexible products. The foundation of our company is our absolute, unyielding commitment to high-quality work and on-time delivery.

Contact us and speak with an engineer about your project at (612) 781-2255, or request a quote online. You will receive a prompt response.

Industrial Custom Products is a one-stop-shop for custom manufacturing and plastic fabrication, including: prototyping and product development, die cutting and dieless knife cutting, thermoforming and vacuum forming, large part thermoforming, CNC plastic routing, fabrication and assembly and drape forming.