Whether you’re new to thermoforming or just learning about the process, it’s important to know your options when it comes to the different types of thermoforming molds available. In this blog, we’ll give you a refresher on what thermoforming is and how it works, share the benefits of the process, explain the mold types available, and help you decide which one is right for your project. Learn what types of thermoforming molds are available for future projects and more.

What Is Thermoforming and How Does it Work?

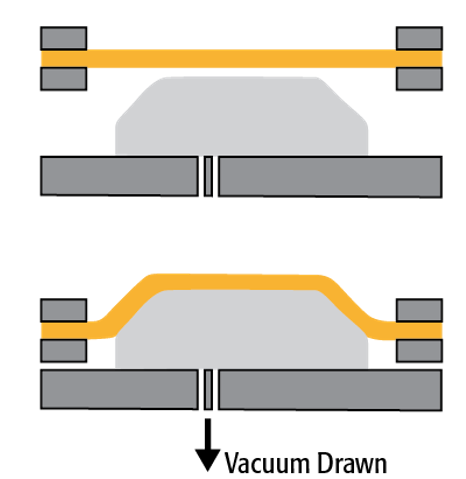

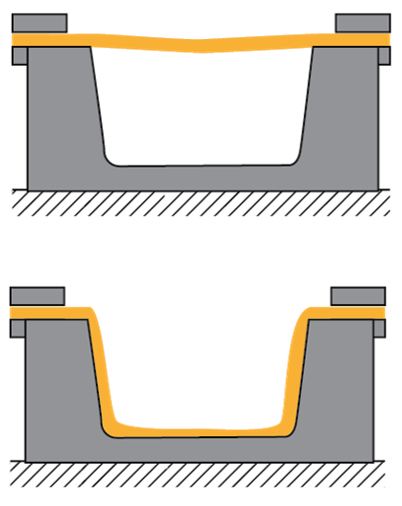

Thermoforming is a manufacturing process that involves heating a plastic sheet to a pliable temperature and forcing it into a vacuum-sealed mold where it then cools and remains the desired shape. After cooling, the part is then trimmed to the desired specifications.

Related Content: Thermoforming Design Basics

Advantages of Thermoforming

There are quite a few advantages of thermoforming in a variety of applications and industries. With its low cost and faster lead times, it’s one of the most efficient tooling options available. Thermoforming boasts numerous advantages, including:

- Wide design flexibility and customization

- Faster lead times

- Cost-efficient and sustainable

- Highly versatile between industries

- Lightweight

- Works with a variety of thermoplastics

Related Content: Injection Molding vs. Thermoforming: What’s Better?

What Types of Thermoforming Molds Are Available?

For thermoforming, there are two key types of molds: male and female. To help you understand what you need in your project, we’ll explain the difference below.

Related Content: What to Know About Thermoforming Molds

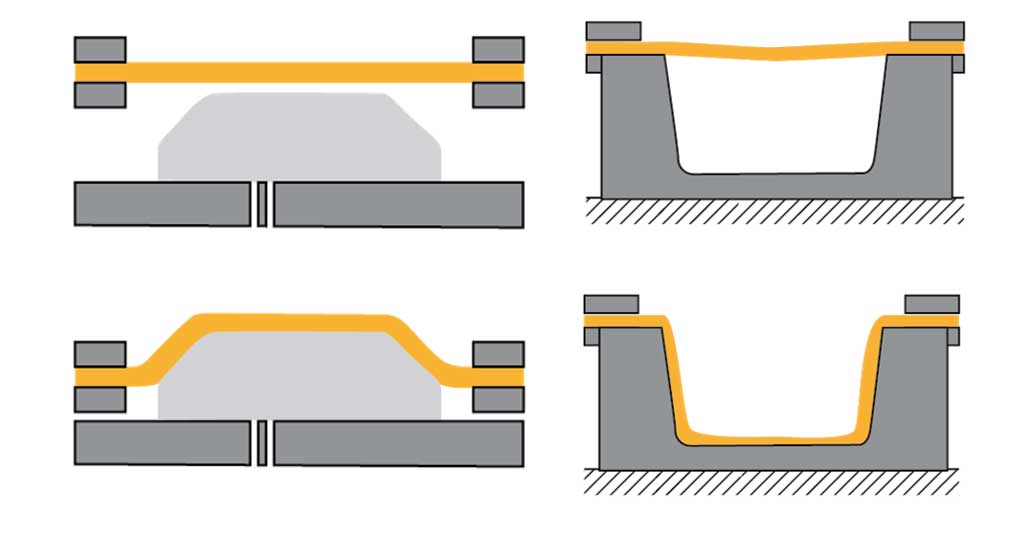

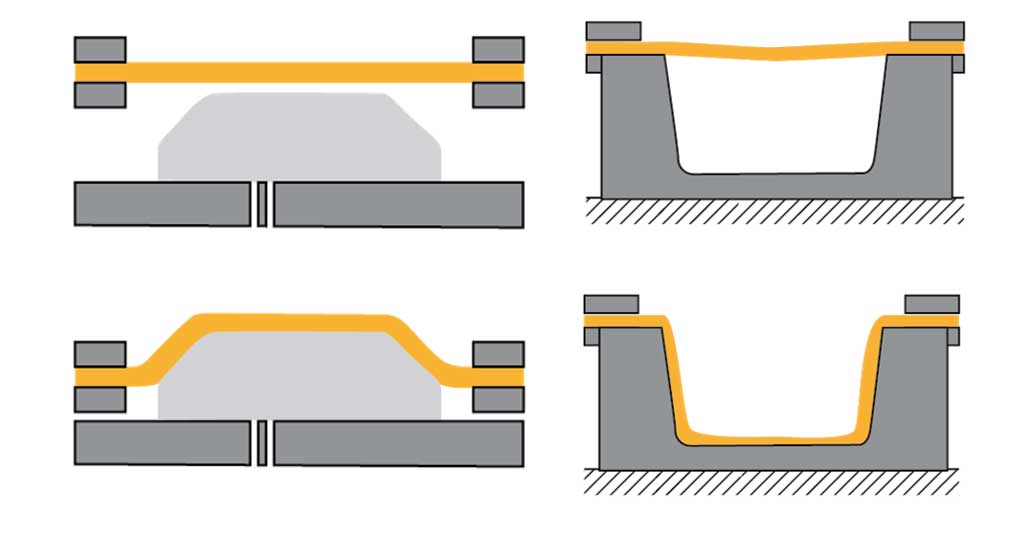

Male Thermoforming Mold

A male thermoforming mold sucks a heated plastic sheet down to form into a part around a mold. This method is great for large part production and is one of the most common thermoforming mold types used.

Female Thermoforming Mold

A female thermoforming mold uses a similar process with a heated plastic sheet, but it’s stretched over a mold and sucked onto the mold rather than the part. This method is widely used for high-detail parts and specific designs.

Related Content: A Guide to Thermoforming Tooling Types

Which Thermoforming Mold is Best for Your Part?

To determine which thermoforming mold is best for your part, use our chart below to compare male thermoforming molds and female thermoforming molds.

|

Male Thermoforming Molds

|

Female Thermoforming Molds

|

|

Texture applied to plastic

|

Texture applied to mold or plastic to match

|

|

No mold marks on the A surface

|

Vacuum holes visible on the A surface.

|

|

Sharp detail difficult to obtain

|

Sharp corners and edges available

|

|

Less surface detail

|

High amount of surface details possible

|

|

Lower cost

|

Higher cost

|

Still have questions after checking out our comparison chart? Speak to a professional at Industrial Custom Products to get answers about your part or what thermoforming mold would work best for your project.

Industrial Custom Products is a one-stop-shop for custom manufacturing and plastic fabrication, including: prototyping and product development, die cutting and dieless knife cutting, thermoforming and vacuum forming, large part thermoforming, CNC plastic routing, fabrication and assembly and drape forming.