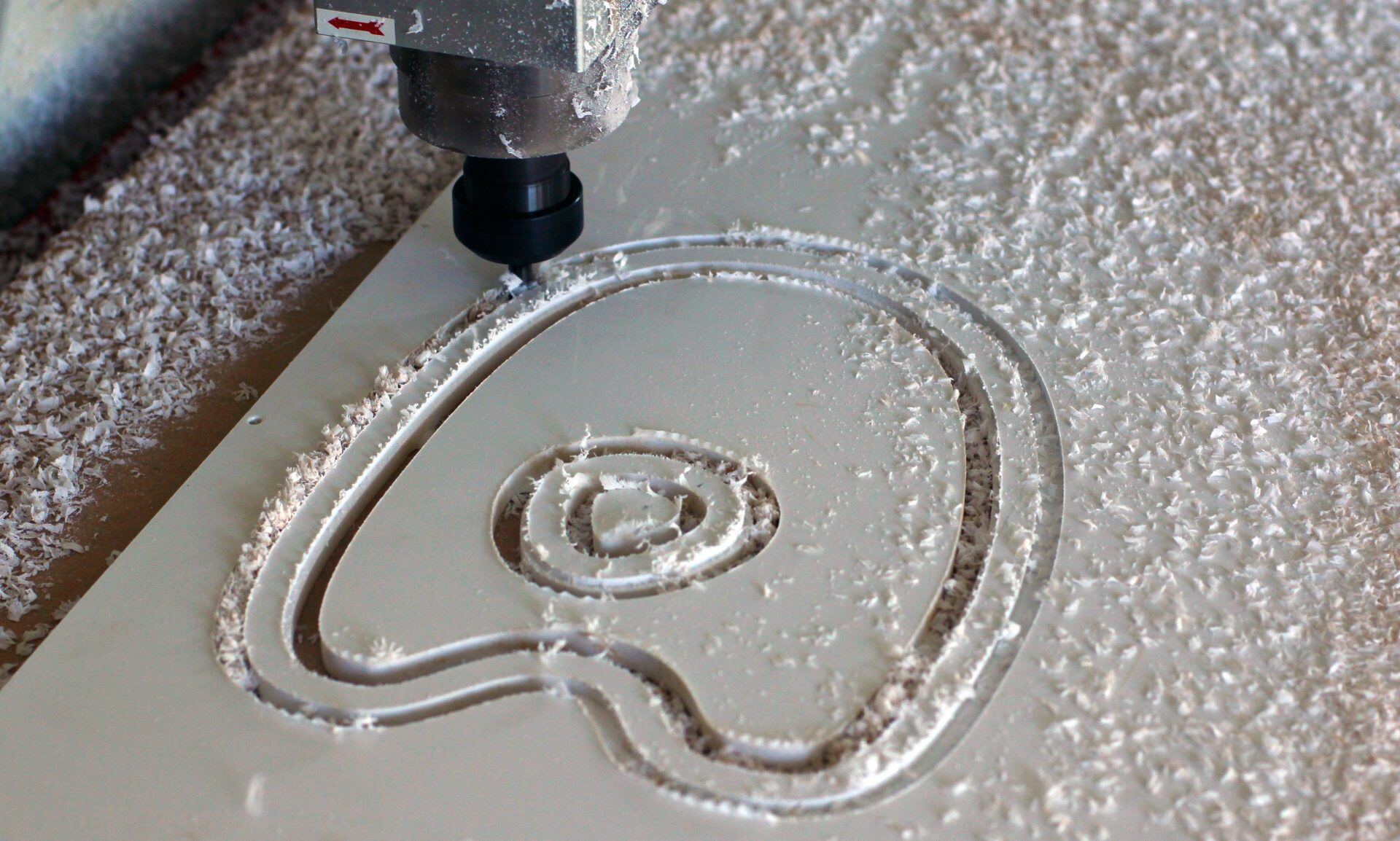

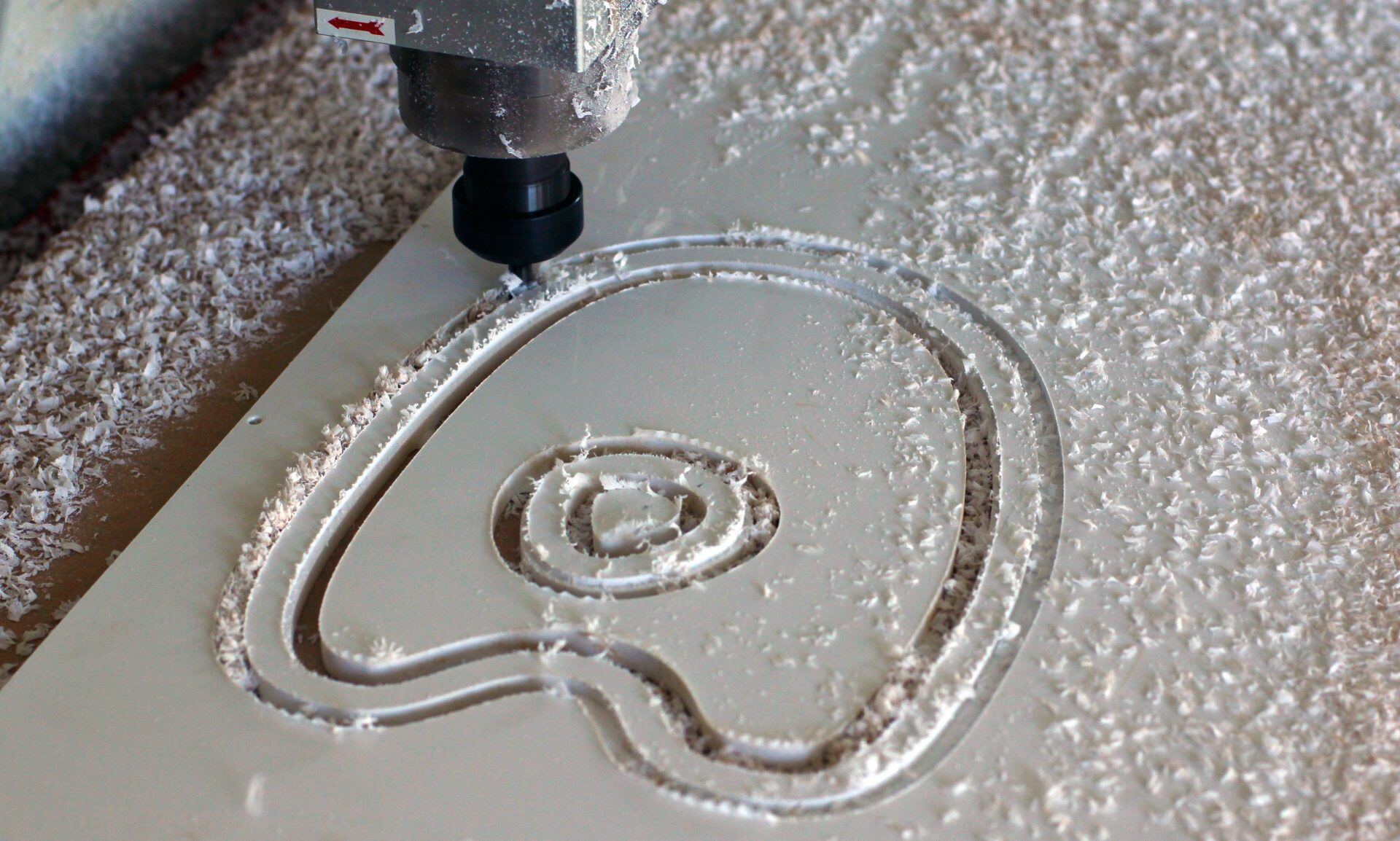

Is your finished plastic part not what you expected? When trimming and edges look funky or are too jagged, the root cause is often an issue in the CNC routing process.

Luckily, these issues can be avoided – if you know what to look for.

The Two Most Common Plastic CNC Routing Issues

Problem: Ugly Cut Edges

Cause: Worn Tooling

Dull cutting tools create a lot of heat and cannot properly eject chips of plastic, causing them to melt on the cut path. This is the number one problem we see, and it’s also the easiest to fix – it’s time to sharpen your tools or replace them if they’re too worn.

Problem: Inconsistent Trimming

Cause: CNC Fixturing

There are two critical factors of fixturing that ensure consistent, repeatable trimming: sufficient fit and vacuum zoning. If the part geometry differs from fixture geometry, the part will not sit on the fixture the same way every time, and the vacuum might not seal properly.

Aside from having a good seal, the vacuum zones need to hold the part in places where part rigidity is lacking.

CNC Plastic Routing with Industrial Custom Products

Our CNC Plastics Routing Services have a proven track record of producing high-quality parts on time. ICP uses state-of-the-art CNC plastic routing equipment, offering the quickest feed rates and programming capabilities while ensuring consistency of the finished product.

Our advanced technology lets us hold tight production tolerances for both 2-dimensional and 3-dimensional parts. That means we route intricate shapes with high repeatability over the entire production run. Rest assured that your parts will exceed your expectations when ICP’s pros get to work.

Our Equipment

QUINTAX – 5 AXIS CNC

- Single head with 8 tool change capacity

3 – THERMWOOD 5-AXIS CNCS

- Twin 5’ x 10’ tables with 6 tool change capacity

THERMWOOD 3-AXIS CNC

- Single head and table with dual vacuum zones

HOLZMA – CNC CUTTING SAW

CNC routing vs. die cutting vs. dieless cutting…with so many processes, how do I choose?

Let us help you decide! ICP offers a wide array of processes, and we can customize a solution to meet your goals. Call or email us to connect with our manufacturing experts, discuss your project, and determine which process works best for you.

Industrial Custom Products is a one-stop-shop for custom manufacturing and plastic fabrication, including: prototyping and product development, die cutting and dieless knife cutting, thermoforming and vacuum forming, large part thermoforming, CNC plastic routing, fabrication and assembly and drape forming.