Design for Manufacturability

ICP partners with your design team early to ensure every part is optimized for cost-effective production. From tool design to material selection, we help you eliminate manufacturing hurdles before they happen.

Design Assist and Optimization

Design Assist and Optimization

Our engineers provide hands-on design support to fine-tune your product for better performance and easier fabrication. We look for opportunities to reduce waste, streamline assembly, and improve performance.

Material Selection Assistance

Material Selection Assistance

Choose the right materials with guidance from our experienced materials specialists. With decades of real-world application knowledge, we understand how plastics, rubbers, and foams behave — in the production, and in the field. We help you balance performance, durability, and cost for the life of your product.

Rapid Prototyping Capabilities

Rapid Prototyping Capabilities

Speed to market matters. ICP’s rapid prototyping services help you move quickly from idea to testable part, accelerating your design validation and reducing development time, all without sacrificing quality.

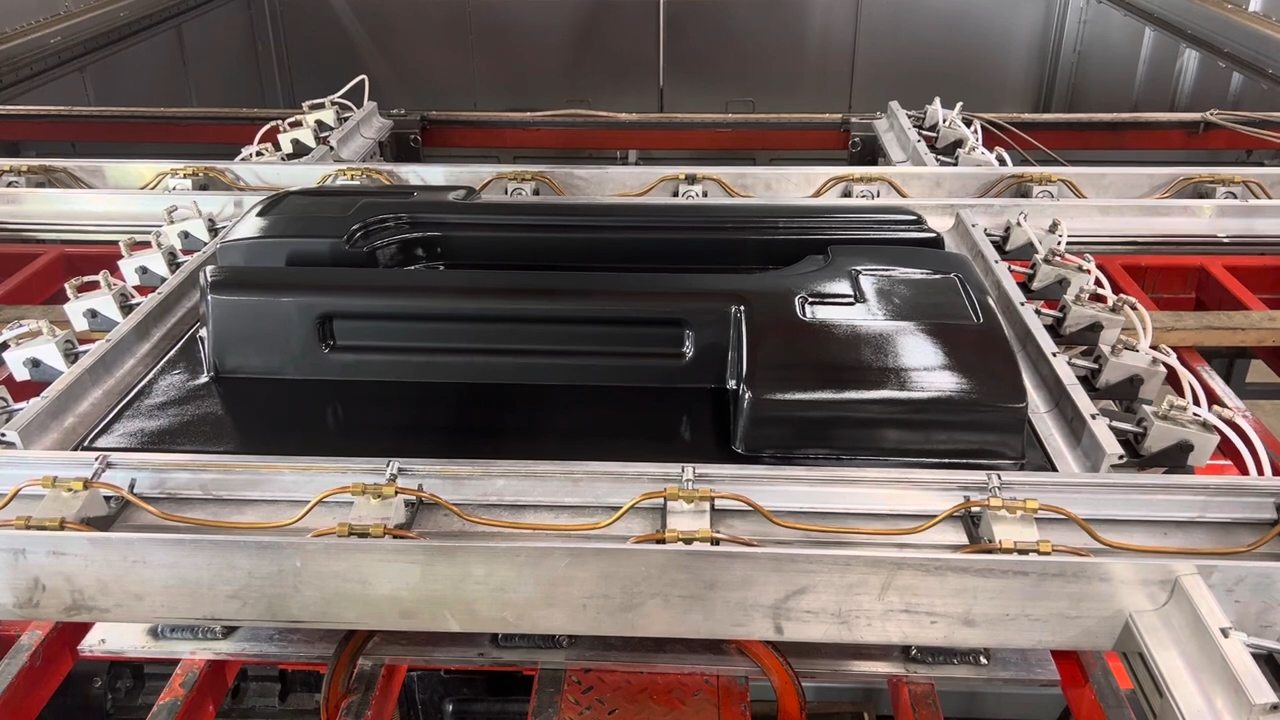

Prototype Tooling

Prototype Tooling

When the market won’t wait, ICP delivers. We offer flexible tooling options to help you meet demanding launch timelines, validate designs, and start production faster.