A key step in any plastic part production is cutting the part to size and removing any unnecessary material to create grooves and other shapes. For 3 dimensional parts, there are two common trimming methods: hand trimming and 5-axis CNC trimming. Between the two options, which one is best?

Our team at Industrial Custom Products is here to help you figure that out. Let’s explore 5-axis CNC trimming vs hand-trimming thermoformed plastics to help you select the best trimming technique for your project.

Related Content: Take Advantage of Custom CNC Routing for All of Your Design Needs

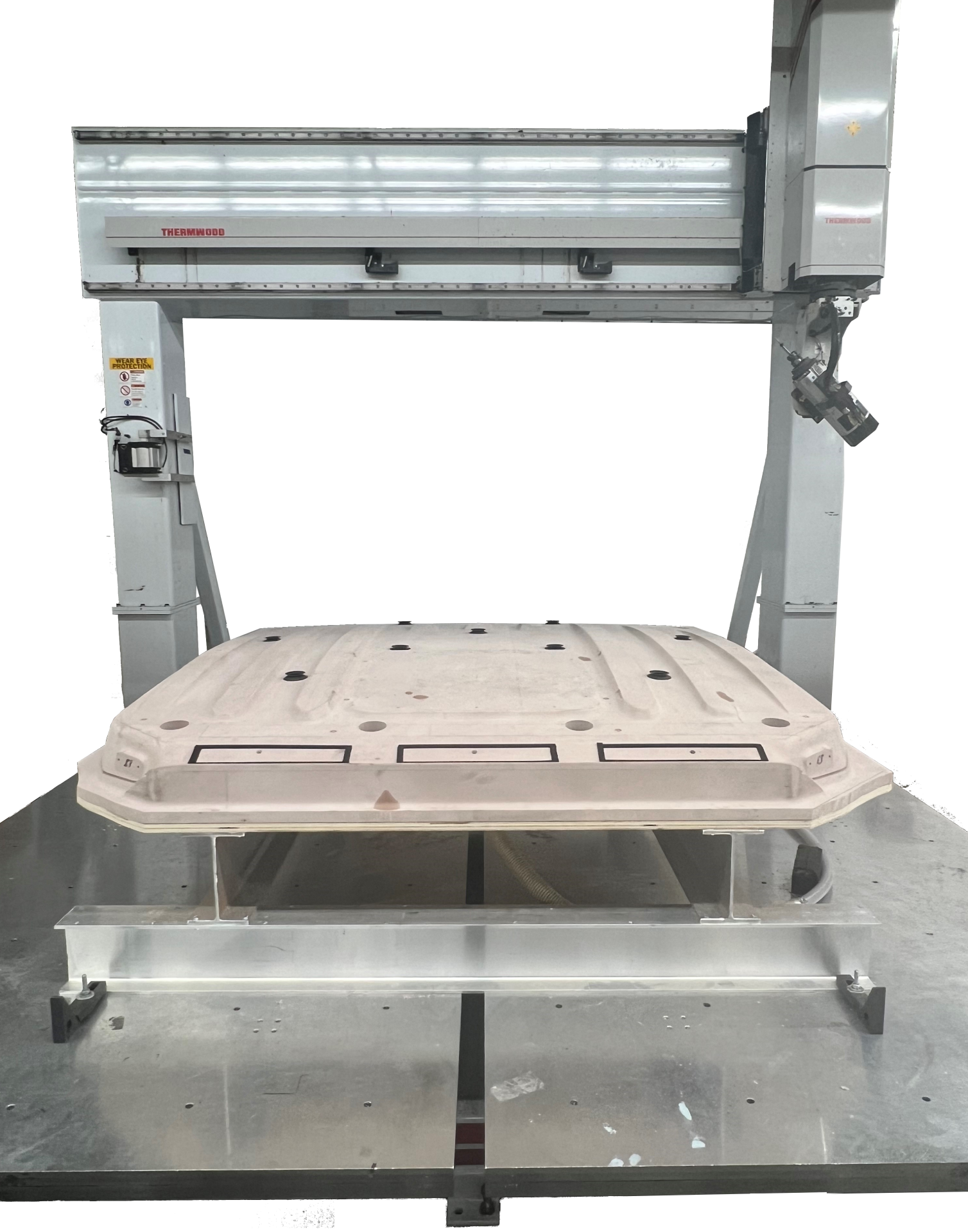

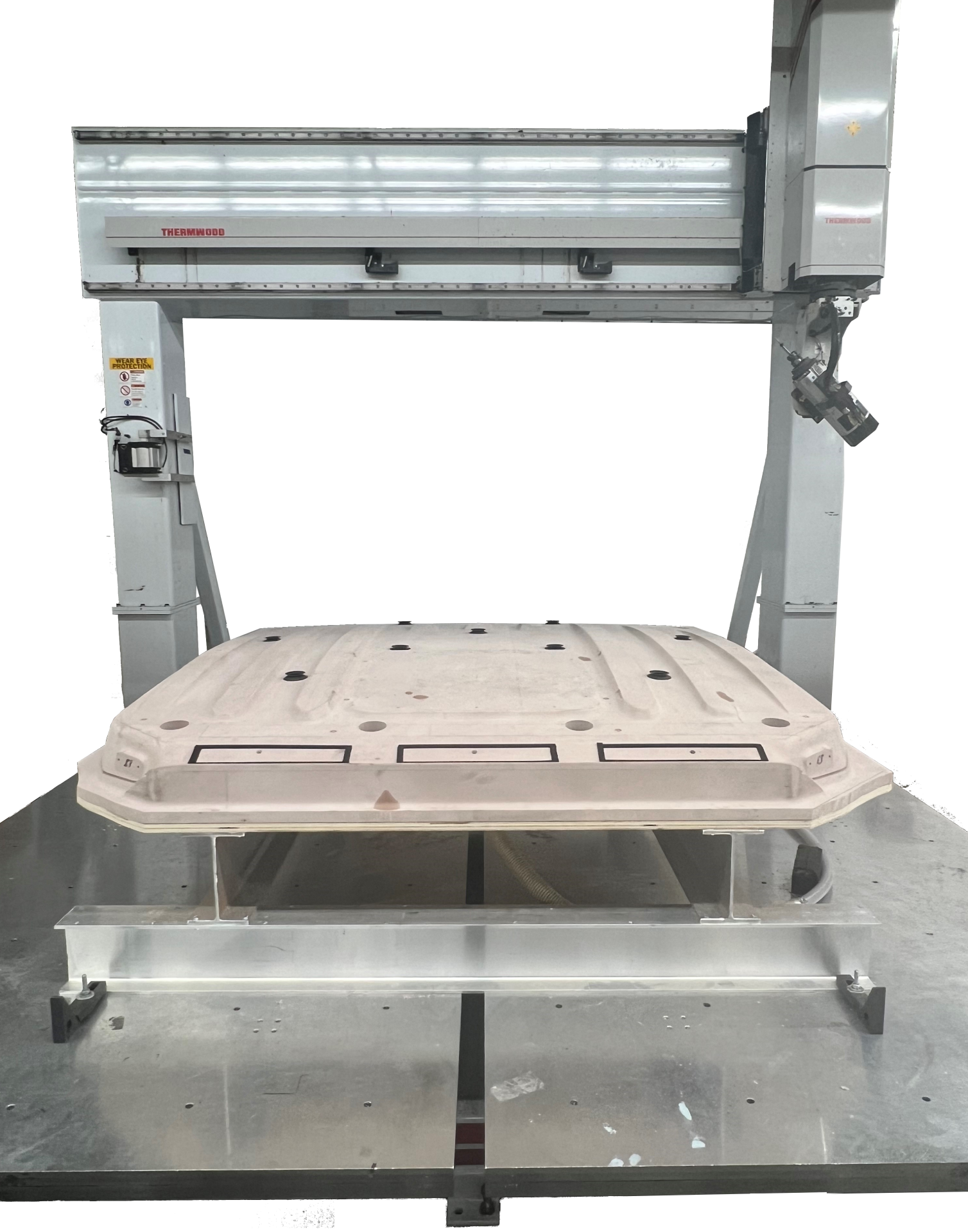

What is 5-Axis CNC Trimming?

5-axis CNC trimming uses a computer numerically controlled machine that follows a pre-programmed CAD/CAM path to precisely trim down manufactured parts. Using three linear axes and two rotational, the design allows for high-speed work and extreme intricacy when it comes to cutting or trimming excess material. Because of the additional axes, it works better for three dimensional parts than 3-axis routing – which is typically used for flat surfaces and two dimensional parts.

Related Content: 3-Axis CNC Plastic Routing Vs. 5-Axis CNC Plastic Routing– What’s the Difference?

Because 5-Axis CNC trimming uses a machine, it’s ideal for both high-volume production and cases where tight tolerances are needed, that might be difficult to do by hand.

5-Axis CNC trimming is ideal for:

- Precision projects with tighter tolerances

- Cutting quality edges

- Matching consistency across parts

- Complex geometries

The 5-axis CNC trimming method works best for precision projects where hand trimming is a great fit for less complex parts.

Hand Trimming

Hand trimming is a manual process that removes excess material from thermoformed plastic parts using hand routers, trim ledges, fixtures, and drills. This is generally used for parts with simple geometry and minimal trimming allowing the part to be finished in cycle during the thermoforming process while passing the savings onto our customers.

Hand trimming is ideal for:

- Simple shapes and easy perimeter trims

- Project cycles (saves time and money)

- Prototyping before larger production runs

- One-off projects and low-volume production

While hand trimming has numerous advantages, it’s important to note that it’s not the best for parts requiring high precision with more complex cutouts.

Related Content: Planning for Material Shrink Rates for Thermoformed Parts

Thermoforming with ICP

Since 1955, ICP has grown to become an award-winning leader in prototyping, developing, and manufacturing high-quality plastic and flexible products. The foundation of our company is our absolute, unyielding commitment to high-quality work and on-time delivery.

Contact us and speak with an engineer about your project at (612) 781-2255, or request a quote online. You will receive a prompt response.

Industrial Custom Products is a one-stop-shop for custom manufacturing and plastic fabrication, including: prototyping and product development, die cutting and dieless knife cutting, thermoforming and vacuum forming, large part thermoforming, CNC plastic routing, fabrication and assembly and drape forming.