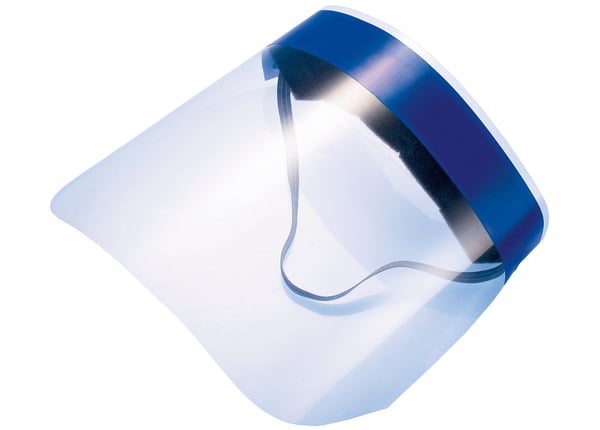

Absolutely. Thermoformed plastic components are widely used in medical equipment and machinery for housings, panels, and protective covers.

When properly designed and manufactured, thermoformed parts can provide consistent quality, smooth surfaces, and reliable performance. ICP works with OEMs to select materials appropriate for medical environments and equipment use.